Microfluidic Cartridge Prototype Production | Hochuen

Hochuen is capable of producing microfluidic cartridge prototypes and other medical devices with good quality at a competitive price. Contact us today.

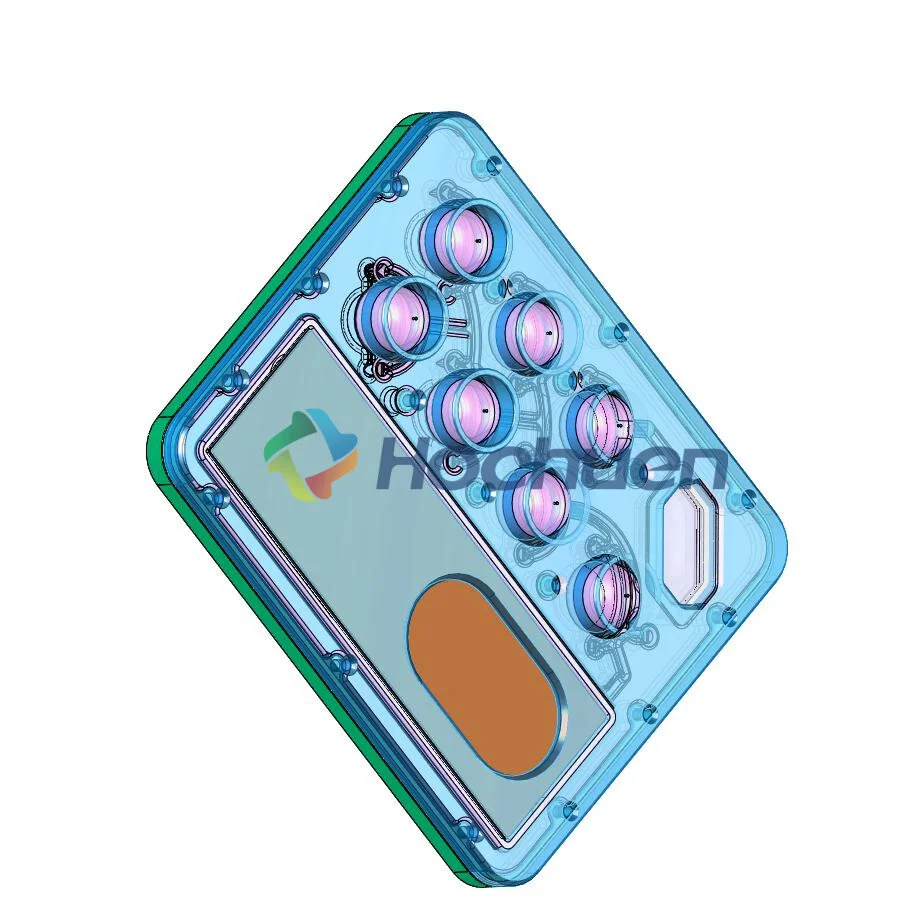

Microfluidic Cartridge Prototype: A Biosensing Process | Hochuen

Hochuen Medical is one of China's major OEM/ODM manufacturers of IVD, medical disposables, and equipment, including Microfluidic Cartridge Prototype.

Body:-

A cleanroom-free rapid prototyping methodology has been used to create a multipurpose Microfluidic Cartridge Prototype for electrochemical biosensing. By overlapping designed thin plastic and adhesive films, a seven-layered CEB platform with gold (Au) electrode substrate can be manufactured. Microfluidic Cartridge Prototype is often required to study how fluid flows through or around various micro-features. Alternatively, it is required to determine how the size of elements such as breadth and depth affect the flow. If the design requires a completely laminar or turbulent flow in the microfluidic channel for proper operation, prototyping is used to determine the ideal channel design and subsequent flow rates.

Difference between Manufacturing and Prototyping of Microfluidics

Are you looking for a prototyping service or a manufacturing vendor to help you create Microfluidic Cartridge Prototype devices? For both cases, the stakeholders compare costs, lead times, and technologies employed. They usually select the best prototyping strategy. It is perhaps high time to take into account the most crucial consideration in transferring Microfluidics concepts to products, which is often overlooked.

Reasons to Adopt Prototype Microfluidic Devices

- For Functional Testing: The most probable explanation is that Microfluidic Cartridge Prototype devices are prototyped to verify their geometry to offer a specific function. This is especially the case if the device's performance is heavily reliant on the extent of its features. Micromixers Traps, in-line flow switches, valves, active micro-particle separators, detectors, and cell culture on-chip, are among the well-known examples of such device applications.

- For Technical Assessment: Many technical queries can be raised about fluid mechanisms in the device model that can be answered by a prototype model, including the design loopholes. Are there any features that produce excessive upstream pressure due to superfluous flow resistance? Is it possible that incorrect channel design causes bubbles to form? An ideal Microfluidic Cartridge Prototype device can suitably settle all possible doubts.

- For Choosing Material for a Microfluidic Chip: To function properly, the microfluidic chip material must have all of the requisite qualities. Microfluidic Cartridge Prototype is developed to assist in material selection, and the feasibility of processing parameters is ideally explored. Optical, mechanical, thermal, and chemical properties are the four basic material constituents to arrive at a perfect material selection process.

- For Visualizing Stability of the Flow: The flow in microfluidic channels often needs to be steady, which means it shouldn't wobble, backflow, or pulsate at nominal fluid velocity. Conversely, if a particle, such as C-Elegans, an organoid, or a cell, needs to be immobilized for gene transfer or imaging, the design must be competent in doing so.

- For Surface Characterization of a Microfluidic Device: Surface features like molecular adsorption, hydrophobicity as well as hydrophilicity, and surface interactions like covalent, or electrical dipole properties or Van der Waals connections between the surface and liquid molecules can all be examined at the bulk material level. It means that a Microfluidic Cartridge Prototype may not be required for testing.

- For Confirming Assay’s Performance in Microchip Surroundings: An assay that performs flawlessly in a Falcon tube, petri dish, PCR tube, or 96 well plates may not function well on Microfluidic Cartridge Prototype chips! Flow conditions, non-mixing due to small size, device impurity, incorrect oxygen or nutrient scheduling, protein absorption, confined dead cells and other factors could all play a vital role. As a result, devices are prototyped to test assay performance under real-time chip settings.

Based on practical experience, the most effective process for saving time and money is to prototype the design at the component level first and then add the pieces to build more advanced Microfluidic Cartridge Prototype modeling techniques.

An integrated cartridge can consist of many different components (e.g., injection molded plastics, blister packs, glass slides, die cut filters, die cut adhesive, heaters, micromotors, dry reagents, etc). The assembly process can also involve various technologies described in the Capabilities section here. In-process ultrasonic cleaning and QC inspection can be implemented as needed.