Microfluidic Chip Manufacturer Board Members | Hochuen

Hochuen Medical, a major microfluidic chip manufacturer, has a strong Scientific Advisory Board that helps in technology development and business strategy.

Lab on a Chip Devices Using Microfluidics is a Technological Marvel

Rise in the number of microfluidic chip manufacturers has put the Lab on a Chip technology in the limelight.

Microfluidics literally puts a laboratory in your pocket and is extremely useful across a wide variety of applications. If you're considering investing in this technology and joining hands with a microfluidic chip manufacturer, here's some key information that may aid your decision-making process.

Microfluidics: A Brief Introduction

Simply put, microfluidics combines technology and science to manufacture microminiature devices containing tiny chambers and using them to study the behavior of different kinds of fluids. The core concept of this technology is to provide a laboratory test on a micro-sized system.

Any microfluidic chip manufacturer can tell you that fluids behave differently in everyday life as compared to on a micrometric scale. This is where microfluidics comes in to aid scientific innovations and experiments involving extremely small amounts of liquids, that can go down to a quadrillionth of a liter.

What Is 'Lab On A Chip'?

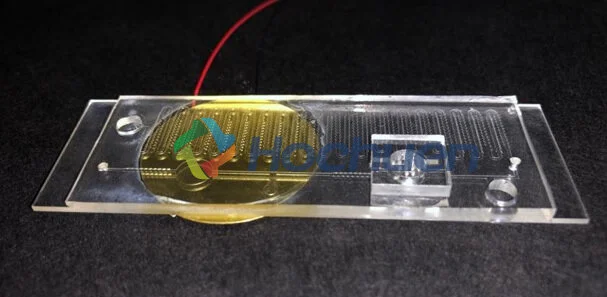

Lab on a Chip is another name for microfluidic chips. These tiny chips encapsulate multiple laboratory processes into one micro-sized device. This miniaturization of multiple processes by a microfluidic chip manufacturer is ideal for diagnostic as well as research purposes, especially in remote locations.

Further research into microfluidics has led to the development of nanofluidics as well. These concepts allow researchers to manipulate small volumes of fluids that are sometimes equal to one-millionth of a liter. The super-thin chambers inside microfluidic chips enable processes like mixing as well as physical and chemical reactions.

A good microfluidic chip manufacturer knows that such a robust technology needs to be simple and fast yet extremely affordable. Of course, it is very difficult to achieve all that, and research labs need to be careful while picking a microfluidic chip manufacturer.

Small Form, Big Advantages

Microfluidic chips offer several advantages, the biggest and the most prominent of which is the compact size of the devices.

The small size helps in situations where research samples and solutions are limited. This is only possible because the tiny chambers inside the microfluidic chip require as little as one-trillionth of a liter, that is a picoliter. This also leaves behind a smaller footprint in terms of chemical waste, thus making it more sustainable than any current technology.

Microfluidic chip manufacturer companies have also proved that their Lab on a Chip devices provide results much faster than manual tests. Because the solution needs to travel an extremely small distance, the reaction is achieved at a faster pace.

But is it really cheap for a microfluidic chip manufacturer to produce such devices on a large scale? The answer is yes, and this has already been demonstrated by Stanford University scientists. They recently managed to produce a chip for early cancer detection, and it cost just a penny to make!

A Promising Futuristic Diagnostic Tool

No microfluidic chip manufacturer has claimed successful commercialization of Lab on a Chip devices. However, the point to be noted that the application of such microfluidic devices in Point of Care Testing (PoCT) could be extremely promising. Healthcare staff performs PoCT tests at patients' bedside. This saves a lot of time and provides faster results for quicker treatments.

Microfluidic chip devices could also be greatly helpful in developing countries, refugee camps, and other regions where medical facilities are limited. Major diseases could be diagnosed early and at extremely cheap costs using these chips. It could also prove beneficial for the early detection and prevention of infectious diseases.

Chronic diseases are tough to tackle due to complex diagnostic procedures that are expensive and lengthy. Microfluidic chips could solve this problem in a jiffy.

If you're trying to find a microfluidic chip manufacturer, you can visit our website for more information.

PDMS (Polydimethylsiloxane) devices can be fabricated using soft lithograph process. Multi-layers of PDMS can be integrated to form complex geometry structure. In-house plasma treatment allows us to achieve robust bonding and sealing. We also have know-hows on bonding PDMS components with other substrates using special adhesive tape.